Industrial Brew

Alfa Laval Industrial Brew centrifuges have a long history of enabling breweries around the world to achieve higher yields, meet shifts in demand and maintain profitability. Used in pre-clarification, green beer separation, hot wort separation and beer recovery, they ensure minimal levels of oxygen pick-up during passage through the separator and the highest standards of hygiene.

Experience the benefits of the Industrial Brew range, high-efficiency beer separation technology:

- Centrifugation provides breweries with swift beer clarification with no loss of aroma

- Enhanced beer quality – longer shelf life, improved haze stability, and preserved aroma and flavour

- High-efficiency beer separation enables quicker tank turnover

- Reduced product loss – beer centrifugation boosts yield by 5–10% compared to traditional gravity settling

- Hermetic Design™ ensures close to zero oxygen pick-up, guaranteed to be below 3 ppb

Clarification through separation helps increase the stability of the final beer. Turbidity measurement system and bowl speed adjustment functionality allow to achieve solids free crystal-clear beers as well as hazy beers.

Innovative features of Brew series beer separators

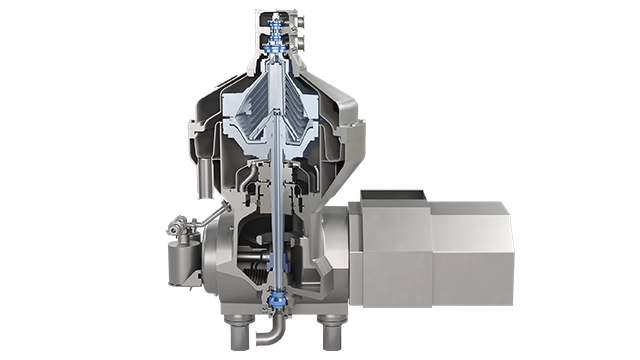

Hermetic Design™

Built with Alfa Laval’s patented Hermetic Design™ concept, the brew series range guarantees extremely smooth and gentle handling, with no risk of air-liquid interface in the bowl. The precise control of product consistency and quality, along with increased flexibility to process different kinds of beer, will bring whole new opportunities into your production. Thanks to the Hermetic Design™, your energy savings can be as high as 60%, and when combined with eMotion™, the savings can reach up to 75% (compared to traditional separation technologies).

eMotion™

Alfa Laval eMotion™ is a unique energy-saving module, available as an add-on for many of Alfa Laval’s separators. By creating a near-vacuum around the separator bowl, eMotion™ reduces air friction to improve energy efficiency. There are additional benefits of eMotion™, such as reduced noise levels, lower cooling requirements, and improved cleanability.

UniDisc™

The Alfa Laval UniDisc™ boosts separation capacity by up to 15% with a hygienic, easy-to-clean design. Its built-in spacers allow more discs per stack, increasing surface area and enhancing performance or flow capacity

Optiwia™: Why is it Important?

Alfa Laval Optiwia™ helps brewers save up to 70% on water use in their clarifying separators. By reusing water for cooling, it reduces costs, improves efficiency, and supports sustainable brewing. Upgrade to Optiwia for a smarter, greener brewing process.

Alfa Laval ConditionAlert™

The new Alfa Laval ConditionAlert gives you an eagle eye’s view of your separator’s performance at all times. ConditionAlert proactively monitors separator condition and sends immediate alerts if actions are needed. Combined with Alfa Laval’s expert analysis, you have the vital information you need to ensure outstanding performance for your separator throughout its long lifetime.

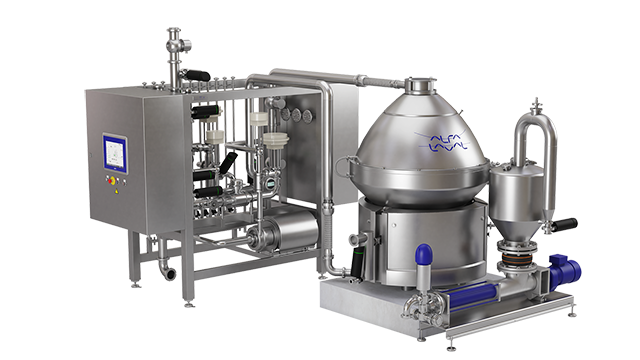

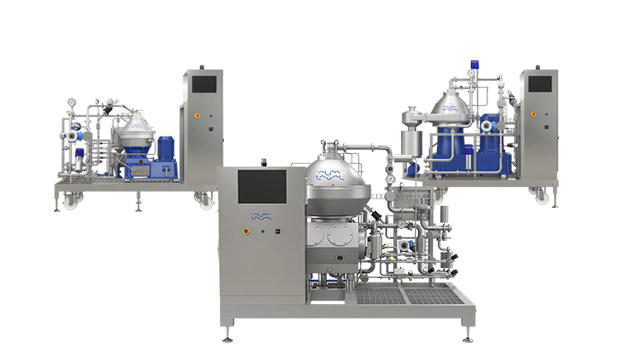

Plug-and-play with complete associated system

The advanced technology of the Industrial Brew range goes far beyond the beer centrifuge itself. To make sure you get the best performance, Alfa Laval can deliver the entire system scope, complete with everything you need to ensure reliable and efficient separation. This includes automation solutions as well as all piping, valves and other relevant process components.

Serija Brew

Naše centrifuge za pivo su se pokazale ključnim u omogućavanju pivarama širom sveta da ostvare veće prinose i veću efikasnost. One obezbeđuju minimalne nivoe nakupljanja kiseonika tokom prolaska kroz separator, što je glavni zahtev kvaliteta za pivare. Higijena je takođe glavni fokus dizajna naših centrifuga za pivare.

Brew 350

Polir za pivare srednje veličine i zanatske pivare

- Do 300 hl/h

- Hermetički dizajn za skoro nulto nakupljanje kiseonika

- Niska potrošnja energije

- Kompletan sistem sa punom fleksibilnošću

- Pokretanje zamućenja ispuštanja čvrstih materija

- Kontrola kapaciteta zamućenjem ulaza

- Siemens ili Allen Bradley automatizacija

Brew 350 Skid

Polir za pivare srednje veličine i zanatske pivare

- Do 300 hl/h

- Hermetički dizajn za skoro nulto nakupljanje kiseonika

- Niska potrošnja energije

- Separator sa kompletnim povezanim sistemom

- Pokretanje zamućenja ispuštanja čvrstih materija

- Kontrola kapaciteta zamućenjem ulaza

- Siemens ili Allen Bradley automatizacija

Brew 450

Zadaci predklarifikacije i poliranja u pivarama srednje veličine

- Do 550 hl/h

- Hermetički dizajn za skoro nulto nakupljanje kiseonika

- Niska potrošnja energije

- Separator sa kompletnim povezanim sistemom

- Siemens ili Allen Bradley automatizacija

- Pokretanje zamućenja ispuštanja čvrstih materija

- Kontrola kapaciteta zamućenjem ulaza

Brew 600

Višestruka namena za veće pivare i zanatske pivare

- Do 650 hl/h

- Hermetički dizajn znači praktično nulti rizik od nakupljanja kiseonika

- Niska potrošnja energije

- Separator sa kompletnim povezanim sistemom

- Pokretanje zamućenja ispuštanja čvrstih materija

- Kontrola kapaciteta zamućenjem ulaza

- Siemens ili Allen Bradley automatizacija

Brew 750

Zadaci predklarifikacije i poliranja u velikim pivarama

- Do 1000 hl/h

- Hermetički dizajn znači praktično nulti rizik od nakupljanja kiseonika

- Niska potrošnja energije

- Separator sa kompletnim povezanim sistemom

- Pokretanje zamućenja ispuštanja čvrstih materija

- Kontrola kapaciteta zamućenjem ulaza

- Siemens ili Allen Bradley automatizacija

Brew 750e

Zadaci predklarifikacije i poliranja u velikim pivarama

- Do 1000 hl/h

- Hermetički dizajn znači praktično nulti rizik od nakupljanja kiseonika

- Izuzetno niska potrošnja energije uz eDrive (direktan pogon) i eMotion (smanjeno trenje vazduha)

- Separator sa kompletnim povezanim sistemom

- Pokretanje zamućenja ispuštanja čvrstih materija

- Kontrola kapaciteta zamućenjem ulaza

- Siemens ili Allen Bradley automatizacija

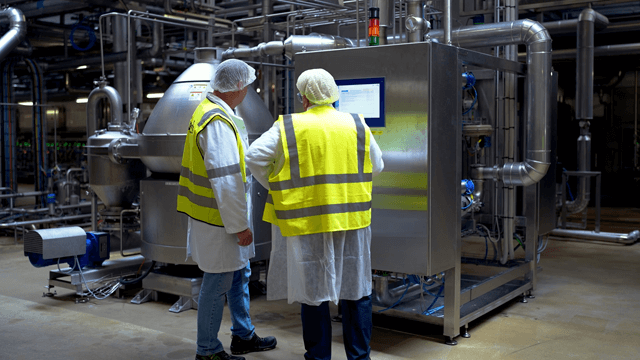

Service

Povećanje performansi vaše opreme

Naša posvećena Globalna servisna mreža podržava vas delovima i stručnošću, gde god da se nalazite, kad god vam zatreba. Obezbeđujući produženi rad, dostupnost i optimizaciju, pomažemo vam da osigurate duševni mir i maksimizirate povrat ulaganja. Možemo sarađivati sa vama na integrisanju naših usluga preko Alfa Laval ugovora o servisiranju za predvidive bezbrižne operacije.

Explore our Craft Brew separators

Do you want to learn more about what Alfa Laval offers craft breweries? Alfa Laval Craft Brew centrifuges focus on delivering unique flavour to your customers. Whether you brew crystal clear lager or hazy IPA, they help protect the character and quality of your beer while improving production efficiency.

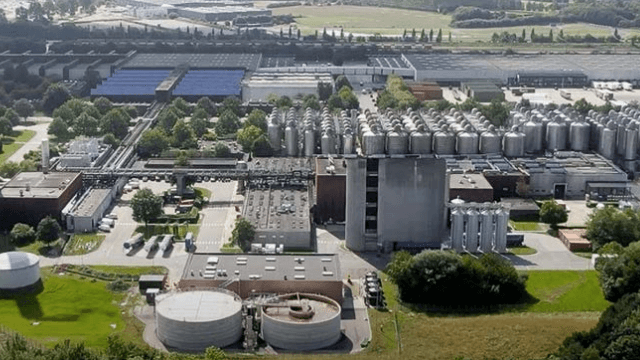

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.