How centrifugal separation works

Centrifugal separation is used across industries such as food, pharma, marine, energy, water, and waste treatment. It separates liquid from liquid and solids from liquids to produce cleaner substances, recover valuable by-products, and reduce waste. Examples include olive oil from paste, cell harvest clarification, fuel cleaning for ship engines, and extracting biofuels from renewable plant-based sources.

Different separation technologies

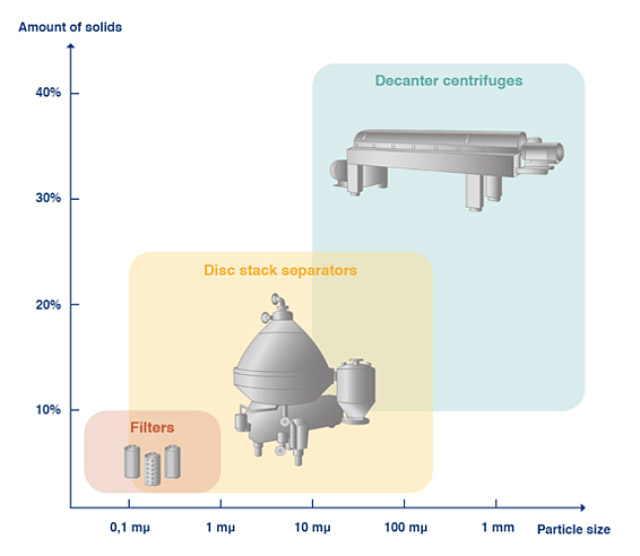

There are various methods for separating liquid phases and solids from liquids. The two most common are centrifugal separation and filtration. Decanters and disc stack separators (also called centrifuges) are both types of centrifugal separators. In many processes, decanters, disc stack centrifuges, and filters are combined - either at different stages or in series - to achieve the required result.

- Decanter centrifuges use centrifugal force to remove large particles from slurries or liquids with a high solids concentration. They can also separate two liquid phases of different densities.

- Disc stack centrifuges apply centrifugal force to separate liquids with lower solids concentrations and smaller particle sizes. They are effective for separating two liquid phases as well as a solid phase.

- Membrane filters handle low solids concentrations, capturing the smallest particles. They typically remove particles up to 1 micron in size from liquids with solids content of 5% or less.

Ranges of each technology

- Decanters: liquids with ≥15% solids, particle size >10 microns

- Disc stack centrifuges: liquids with <25% solids, particle size 0.1–150 microns

- Filters: liquids with ≤5% solids, particle size <1 micron

- Membrane filters: liquids with ≤5% solids, particle size up to 1 micron

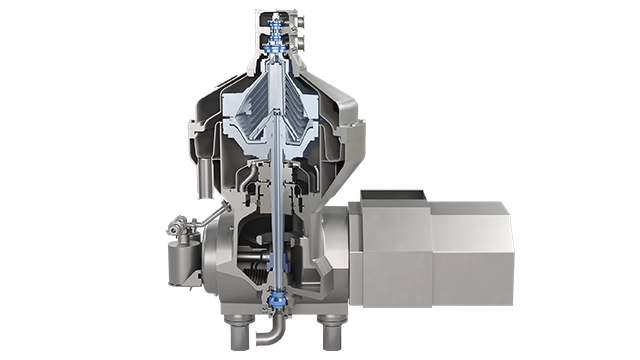

How a disc stack centrifuge works

Separation technology involving a disc stack separator/centrifuge is used for centrifugation in which various phases of solids and liquids are isolated from one another based on the difference in densities.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.