Lynx

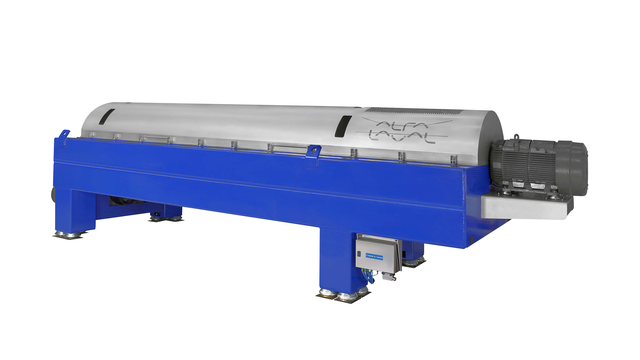

The Alfa Laval Lynx decanter centrifuge is a key component in solids-liquid separation for oil, gas and drilling industry processes such as barite recovery and slop oil. It is specially designed for heavy duty and high recovery at large feed flows and has the best available wear protection. It is also available as a three-phase version for separation of oil, water and dry solids.

High performance decanter centrifuge

- Unmatched levels of product recovery in continuous operation

- High capacity on market’s smallest footprint

- Low labour cost due to less operator intervention

- Suitable for any harsh conditions

- Robust and trusted technology

Lynx decanter centrifuges can be tailored to specific requirements using options such as advanced wear protection, automated controls and remote monitoring. They are available as 2 or 3-phase designs. The bowl and conveying speed, pond depth in the bowl and feed rate are all adjustable to support optimum performance. We also cater for EX classification Zone 2 as well as Zone 1.

What makes the Lynx decanter centrifuge different?

FlightGuard

FlightGuard wear protection consists of tiles welded to the conveyor,

providing robust wear resistance and prolonged uptime in highly abrasive

applications.

SolidsGuard

360° outlet design with enhanced, replaceable wear protection for highly

abrasive media, ensuring high uptime.

FeedGuard

FeedGuard

The fully covered FeedGuard feed zone ensures

gentle product acceleration and minimal turbulence,

resulting in low wear and tear. The FeedGuard

design provides outstanding reliability and uptime in

abrasive applications, as well as easy on-site

replacement, reducing downtime.

EasyLift

EasyLift

The patented, spring-loaded, hinged design makes

it easy to open even the heaviest cover by hand.

Offering safe and quick access for maintenance

and service.

PowerTubes

PowerTubes

Adjustable outlets are designed to release the liquid

tangential to the rotational direction. This supports

the bowl rotation and thereby recovering energy

and minimizing power consumption.

How the Lynx decanter centrifuge works

The Alfa Laval Lynx decanter centrifuge is built around a slender cylindrical bowl with a relatively large length/diameter ratio and a conical end. This bowl rotates at speeds of up to 4000 rpm (depending on model) producing a centrifugal force of anywhere from 300 to 3574 G. The other key components include a main drive motor, heavy-duty gearbox, back drive motor and an AL automation solution. The unique Alfa Laval direct drive gearbox ensures automatic control of the conveying speed.

The liquid is fed into the long cylindrical bowl where the centrifugal force presses it outwards to form a layer (known as the pond) on the wall of the bowl. The thickness of this layer is determined by a series of discharge weirs at the end of the cylindrical section. The clarified liquid flows out over these weirs with the aid of centrifugal force. Since the solids in the mud are heavier, they remain on the bowl wall, and are continuously removed by the screw conveyor. They are then transported up to the conical section (known as the beach) where they exit via the discharge ports at the narrow end. Cleaned liquid exits at the opposite end.

3-phase design

In 3-phase separation, the decanter has a pairing disc installed which separates the light phase from the heavy phase via a pump and level tube action. This enables you separate both solids light phase and heavy phase in the same operation without adding a second step.

Liquid-liquid separation

Special versions of the Alfa Laval Lynx decanter centrifuge can be used for liquid-liquid separation (for example oil from water) to deliver liquids of a clarity never before achieved using decanter centrifuges. The availability of online inter-phase adjustment, with no need for mechanical changes, makes it easy to optimize the quality of the separated liquid phases.

The separation into two liquid phases takes place over the entire length of the cylindrical part of the bowl, and the clarified heavy and light liquid phases are discharged from the bowl by flowing over different sets of level tubes.

Visit our product catalog

The Alfa Laval product catalog an easy-to-use tool to help you filter, select and quote the best solution. Enter the online catalogue and select your products and parts.