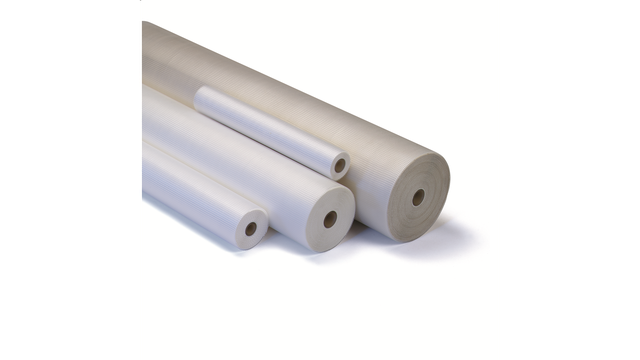

UF spiral

The Alfa Laval ultrafiltration spiral membranes are a proven and popular choice for many processes in the food, beverage, dairy, biotech and pharmaceutical industries where they are used for product recovery as well as product purification, fractionation and concentration. This makes the spiral membranes for ultrafiltration one of our most versatile products. Alfa Laval offers a comprehensive range of spiral UF membranes with different characteristics and properties.

Experience plant efficiency with ultrafiltration membrane technology

- Excellent resistance and tolerance for food-based applications, supporting safe and reliable operation in sensitive processes

- A preferred choice for precision fermentation, thanks to consistent performance and reliability

- Available in a range of material types, providing a broad portfolio for diverse requirements

- Wide range of molecular cutoff options (from 2k Dal to 100k Dal) enables tailored separations for specific needs

- High capacity and low energy consumption achieved through an optimized fit between element and housing, maximizing efficiency

Optimized spiral wound UF membranes

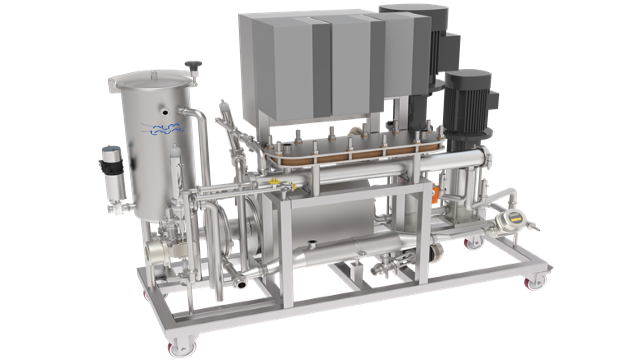

Alfa Laval ultrafiltration membranes are recognized for their exceptional durability and superior chemical and thermal stability. Offered as flat sheets for laboratory testing and spiral elements for large-scale operations, they enable seamless scale-up and deliver cost-effective performance with lower energy consumption compared to other membrane filtration methods, such as reverse osmosis. They are also highly efficient, eliminating the need to replace or dispose of cartridges and consumables used in traditional dead-end filtration.

With the new addition of DuroLac™ UF spiral membrane elements, we are now offering up to 15% increase in permeate output per element, significantly boosting plant performance.

Our spiral wound UF membrane materials comply with all major industry regulations, including EU Regulations 1935/2004, 10/2011, and 2023/2006, as well as FDA CFR Title 21. Related equipment, such as plate-and-frame modules and auxiliary equipment, is also compliant, ensuring safe and efficient filtration across food and pharmaceutical applications.

How do spiral wound UF membrane work?

Ultrafiltration (UF) operates at moderately low pressure (typically 1–10 bar) to separate particles suspended in a liquid through a semi-permeable membrane. Its working principle relies on a spiral UF membrane with pore sizes between 0.01 and 0.1 microns, which selectively separates molecules based on molecular weight cut-off (MWCO) and other factors such as electrical affinity. This membrane filtration method is widely used for water purification (removing bacteria and viruses), enzyme retention, as a pre-treatment for reverse osmosis, and for polysaccharide and protein concentration in the dairy, food and beverage industries.

Engineered for reliability and performance, the entire Alfa Laval spiral-wound membrane range and associated equipment meet all major regulatory standards, ensuring safe and consistent operation in hygienic and sensitive processes.

Optimize dairy plants with DuroLac™ UF Spiral Membrane Elements

The goal of a dairy plant is to continually increase efficiency and performance while protecting or improving plant capacity. We acknowledge these priorities and have developed a new range of spiral wound membrane elements, namely the DuroLac™ UF spiral membrane elements.

- Boost efficiency and performance: Achieve up to 15% increase in permeate capacity per element, enhancing overall plant efficiency and performance.

- Reduce energy use: Lower energy consumption during production and cleaning, contributing to a more sustainable operation.

- Lower utilities consumption: Decrease water and CIP chemical usage, enhancing sustainability and cost-effectiveness.

Alfa Laval offers different ultrafiltration membrane technology

The ultrafiltration spiral membranes range from 1,000-100,000 molecular weight cut off (MWCO), and the applied pressure is relatively low. Salts, sugars, organic acids and smaller peptides pass through the pores while proteins, fats and polysaccharides are retained.

With our spiral wound UF membranes you can fractionate a feed stream into two distinct streams, with each stream containing dissolved components with different molecular weights.

UF-pHt™ series

- UF-pHt™ membranes tolerate high temperatures and pH values. The membranes are made of polysulphone or polyethersulphone on polypropylene support material. MWCO values range between 2,000 and 100,000 Da. Most of the spiral UF membrane are USDA approved and Halal certified.

UF-PP series

- The UF-PP membranes are made of fluoro polymer, polysulphone, regenerated cellulose acetate or composite fluoro polymer on polypropylene support material. MWCO values range from 1,000 to 100,000 MWCO. One type is Halal certified.

UF-PET series

- The UF-PET ultrafiltration spiral membranes are based on polyester support material. The polymeric membrane is made of polysulphone, polyethersulphone or regenerated cellulose acetate with up to 100,000 MWCO values. Certain types are USDA approved and we can offer products with Halal certificates upon request.

Dairy series

Alfa Laval has two series of spiral wound membranes tailor-made for dairy applications: Dairy UF-PET and the Dairy UF-pHt™.

- The dairy UF-PET spiral membranes, which are manufactured with polyester support material, are available with MWCO values between 5,000 and 10,000 Da.

- The dairy UF-pHt™ spiral membranes, which are cast on polypropylene backing paper, are available with MWCO values between 5,000 and 20,000 Da.

Both types are USDA approved and we can offer products with Halal certificates upon request.

Ready to take the next step?

Submit the form and let our application experts guide you with ultrafiltration testing solutions, compliance details and scale-up support.