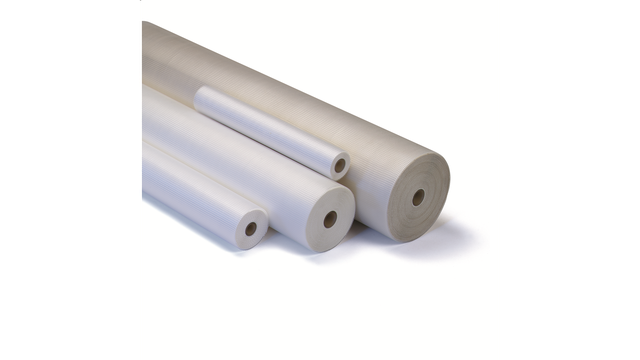

RO spiral

Alfa Laval reverse osmosis spiral membranes are low energy, proven solutions for concentrating feed streams, particularly heat sensitive products. The spiral RO membranes can also be used for pre-concentration prior to evaporation as well as product and water recovery from permeate streams and evaporator condensate. Made of thin-film composite cast on either polyester or polypropylene backing paper, our two series of reverse osmosis spiral membrane have different NaCl rejection properties.

Proven design and membrane technology to enhance your RO process

- The only polypropylene (PP) based RO spiral available in the market, supporting higher temperatures and pH ranges during cleaning-in-place (CIP)

- Effective for further treatment of other filtration processes, e.g. recovering byproducts from UF system permeate, adding value to integrated systems

- Maintenance is straightforward, with low service costs and easy replacement, thanks to a user-focused design

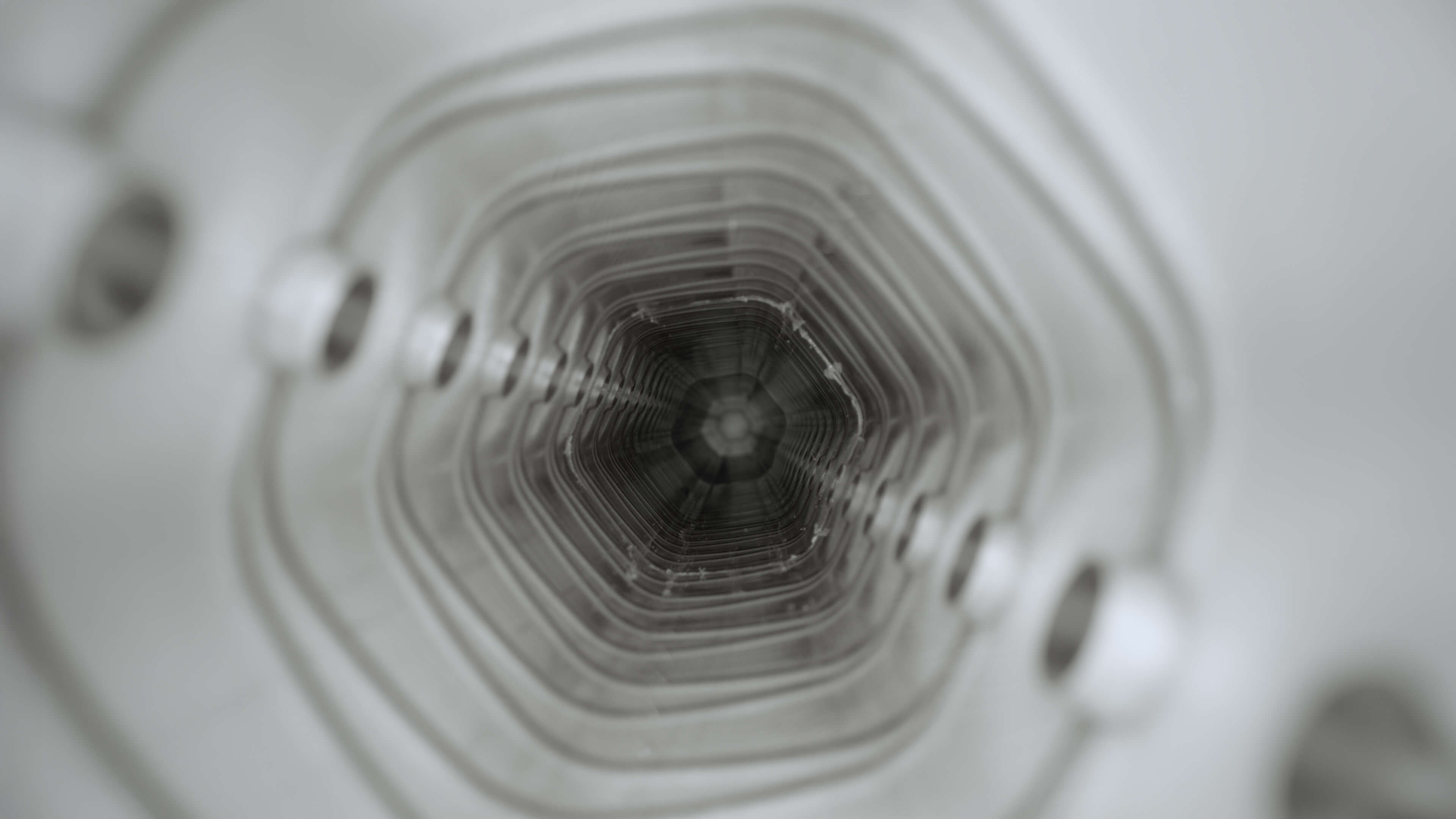

- Patented hexagonal permeate tube design enhances mechanical strength and operational efficiency, setting these spirals apart

- Delivers consistently high rejection rates and product quality, making it a strong choice for demanding applications

Optimized spiral RO membranes with innovative features

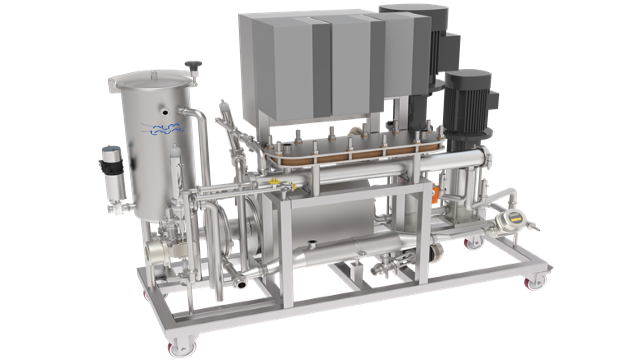

For decades, Alfa Laval’s expertise in spiral reverse osmosis membrane filtration has been valuable both for testing new processes and scaling-up operations that demand very high-quality permeate water and the recovery of valuable resources, such as in pharmaceutical and food & beverage manufacturing.

Endurance is built into every layer of Alfa Laval reverse osmosis (RO) spiral membranes, and a patented hexagonal permeate tube strengthens the core and optimizes flow. We offer the only polypropylene (PP)-based RO spirals on the market, capable of withstanding higher temperatures and wider pH ranges during CIP cleaning, making them deliver exceptional efficiency for water purification and demonstrating outstanding chemical and thermal stability with a service life that spans years.

About our reverse osmosis membrane range

RO PE Series

- The reverse osmosis spiral membranes of the RO PE series, RO99 and RO90, have a NaCl rejection of ≥98% and ≥ 90% respectively.

RO98 pHt™ Series

- This version has a pHt™ spiral reverse osmosis membrane that tolerates temperatures and pH higher than the RO PE series. The RO98 pHt™ has a NaCl rejection of ≥ 98%.

All types are USDA approved and comply with major international regulations, including EU (EC) 1935/2004, EU 10/2011, EU (EC) 2023/2006 and FDA CFR Title 21. Upon request. we can offer products with Halal certificates.

Should you need to evaluate which membrane type your process requires, Alfa Laval reverse osmosis RO membranes are also available as flat sheet membranes to be installed in plate-and-frame membrane modules for screening or lab work.

How do spiral RO membrane work?

A reverse osmosis RO spiral membrane is built from multiple membrane 'envelopes' with two membrane sheets separated by a permeate spacer mesh, each glued to a central permeate collection tube. Feed spacers between the envelopes create channels that guide the feed/retentate flow across the element.

The minuscule pores of Alfa Laval RO membranes only allow small fractions of salts to pass through along with the water, the prime component of the permeate. Certain organic compounds with low molecular weights may also pass through but only to a limited extent. However, the membrane will retain for any other components (salts, sugars, etc.) suspended or dissolved within the liquid flow.

The permeate that passes through the membrane travels within each envelope and moves in a spiral path toward the central permeate tube, where it is collected and directed out of the element. This configuration enables efficient separation, high surface area in a compact design and consistent performance in RO filtration applications.

Explore related products

If your process demands additional filtration steps before or after reverse osmosis, Alfa Laval offers a full range of complementary membrane technologies. Our portfolio includes microfiltration (MF), ultrafiltration (UF), and nanofiltration (NF) solutions, as well as pilot testing units to help you evaluate and optimize performance across every stage of your filtration process.

Reach out for expert guidance

Submit your request and our engineers will help you find the right solution to your specific needs.