NF spiral

Alfa Laval nanofiltration spiral membranes (NF) are proven solutions for the high-yield concentration and demineralization of products such as antibiotics, whey and ultrafiltration permeate. They retain salts with a divalence in excess of 1 while small monovalent salts pass into the permeate. Our nanofiltration membranes can also be used for producing low-alcohol beverages with the alcohol component passing through the NF membrane, while the colour and aroma remain in the retentate.

Reduce overall production costs and boost product quality with NF spiral membranes

- High salt selectivity with options for different selectivity levels, allowing precise tuning for specific process needs

- Enables concentration and purification in a single step, simplifying workflows and reducing process complexity

- Particularly efficient for peptide concentration, delivering reliable results in specialized applications

- Best membrane for charge-sensitive feeds, ensuring appropriate filtration where it matters most

- Provides a cost-effective solution for dairy and similar applications, with proven performance

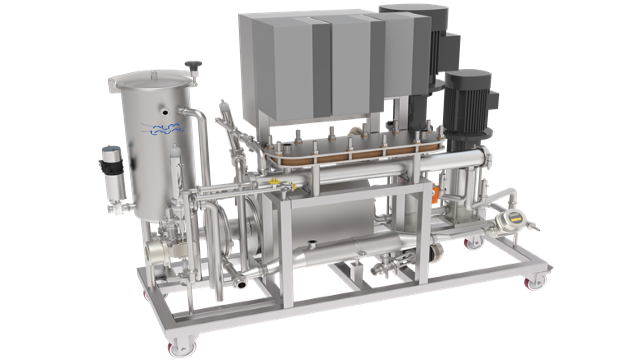

Compact design and seamless integration with Alfa Laval spiral membranes

Alfa Laval has been a trusted partner in membrane filtration solutions for more than 50 years, offering a complete portfolio that includes two series of nanofiltration membranes with different salt rejections and flux properties, engineered to make your concentration and purification processes simpler, faster and more efficient. By combining both steps into one, they are the preferred spiral membrane solution for peptide concentration and handling charge-sensitive feeds. For dairy manufacturers, they offer a proven, cost-effective solution thanks to low energy use, flexible configurations across element sizes and spacer options, and the ability to desalinate and concentrate at the same time.

With a compact footprint that fits easily into any existing system, Alfa Laval nanofiltration membranes are simple to integrate. Their space-efficient design, high chemical and thermal tolerance, and service life spanning several years provide cost-effective performance across biotech, pharmaceutical, dairy, food and beverage processes.

Alfa Laval's range of nanofiltration membranes

The NF spiral membranes, which are manufactured in-house at our own dedicated production facility, use a unique construction of a thinfilm composite polyamide membrane with polyester (PET) support material. Suitable for a wide range of high-sanitary processes, Alfa Laval’s portfolio includes different membrane types and multiple combinations of element length, diameter and feed spacer size, providing flexibility to match specific process requirements.

NF Membrane Series

The NF Membrane Series comes in two types of spiral-wound membranes for nanofiltration: NF and NF99HF. Both spiral membrane types are made of thinfilm composite membrane cast on a durable polyester support. Recommended for processes requiring precise salt control since they deliver exceptional separation efficiency with a rejection rate of ≥99% for divalent salts, based on magnesium sulfate testing.

All nanofiltration membrane materials used for the production of the NF spiral membrane comply with EU Regulation (EC) 1935/2004, EU Regulation 10/2011, EU Regulation (EC) 2023/2006 and FDA regulations (CFR) Title 21. In addition, Alfa Laval nano filtration membranes can be Halal certified and USDA approved upon request.

Should you be interested in our testing solutions, Alfa Laval membranes for ultrafiltration are also available as flat sheets to be installed in plate-and-frame membrane modules for industrial operation.

How does nanofiltration work?

Nanofiltration (NF) uses pressure to push liquids through semi-permeable membranes in order to separate substances based on size and charge (repulsion). NF pore size allows only certain molecules and ions to pass while retaining others. A moderate pressure is required for nanofilters to operate effectively.

Membrane Structure

Alfa Laval NF membranes are thinfilm composite layers cast on a polyester support. They have pore sizes down to ~300 Daltons, enabling precise molecular separation.

Operating Conditions

At pressures up to 55 bar, water and small ions permeate through the spiral membrane, while larger ions and organics remain in the retentate, creating two streams: Permeate (Purified water with small ions) and retentate (Concentrated salts and organics).

Selective Permeation

Small molecules and monovalent ions (e.g., sodium, chloride) can pass through the membrane pores, while divalent ions (like calcium and magnesium) are retained.

Explore related products

For applications requiring other types of membrane selectivity, Alfa Laval provides NF, UF and RO spiral-wound membranes as well, together with pilot-scale testing systems to validate process performance.

Looking for expert guidance?

Whether you need advice on nanofiltration membrane materials, testing, or scale-up possibilities, we’re here to help. Simply submit the form and connect with Alfa Laval specialists.