MF spiral

Alfa Laval MF membranes in spiral wound configuration are proven solutions for efficient removal of dispersed solids. Each microfiltration membrane is designed with a robust structure, utilizing a polypropylene (PP) support layer in a sanitary, full-fit construction to ensure optimum filtration. We manufacture and supply different types of microfiltration membrane materials and various combinations of length, diameter and feed spacer size to deliver the right performance for your application.

Experience efficient filtration without affecting the balance of components dissolved in the stream

- Effective in select specialized applications, offering targeted filtration solutions where standard membranes may not suffice

- Designed for low energy consumption, helping to reduce operational costs and environmental impact

- Performs well in high temperature and pH environments, supporting demanding process conditions

- Especially suitable for high-temperature applications where other spirals may not be as effective

- Built for reliable, consistent performance, supporting long-term operation in challenging environments

Precision microfiltration for screening and scale-up operations

With over 50 years of experience in membrane technology, Alfa Laval offers two series of MF membranes with different pore sizes and microfiltration membrane materials. Manufactured in-house at our specialized facility, MF spiral membranes use either polysulphone polymer or fluoro polymer on a polypropylene support, ensuring flexibility for a broad spectrum of applications.

Whether you are testing or operating at a large scale, our spiral membranes provide a compact solution that delivers cost-effective operation through low energy consumption, eliminates the need for disposable cartridges used in traditional dead-end filtration and offers exceptional durability with chemical and thermal stability for service lives of several years. If you wish to evaluate which membrane type your process requires, Alfa Laval microfiltration membranes are also available as flat sheet membranes for screening or lab work.

A wide range of spiral wound microfiltration membranes

Our microfiltration membranes are available in two different materials and a number of pore sizes to ensure that you find the right one for your application.

MFG series

Made from durable polysulphone polymer, Alfa Laval’s MFG microfiltration membranes are designed to deliver reliable performance and maximum filtration.

- MFG1: Pore size of 0.1 µm, commonly used when a high level of clarity and protection is required in your process.

- MFG2: Pore size of 0.2 µm, suitable for applications where flow rate is more important and the particles to remove are slightly larger.

MFP series

The portfolio of MFP microfiltration membranes are made of fluoro polymer and come in two pore sizes:

- MFP2 with a pore size of 0.2 µm

- MFP5 with a pore size of 0.5 µm, designed for faster flow and handling larger particles.

Upon request, Halal-certified products are available to meet your specific standards. All microfiltration membrane materials used in both flat sheet and spiral wound configurations comply with major international regulations, including EU (EC) 1935/2004, EU 10/2011, EU (EC) 2023/2006 and FDA CFR Title 21. Compliance also extends to related equipment and fittings, ensuring safe and efficient spiral membrane filtration across food and pharmaceutical applications.

Should you be interested in our testing solutions, Alfa Laval membranes for microfiltration are also available as flat sheets to be installed in plate-and-frame membrane modules for industrial operation.

How do MF spiral membranes work?

Microfiltration MF membranes work by allowing liquids and tiny molecules to pass through their pores while retaining larger particles like bacteria, fat globules, cells and suspended solids. Although the pore sizes are very small (~0.1 to 1.0 µm), they are still larger than those used in other membrane filtration processes such as ultrafiltration (~0.01 to 0.1 µm), nanofiltration (~0.001 µm) and reverse osmosis (~0.0001 µm). Because of this larger pore size, MF provides excellent filtration with less flow resistance, which requires relatively low transmembrane pressure (TMP) and results in lower energy consumption.

Explore related products

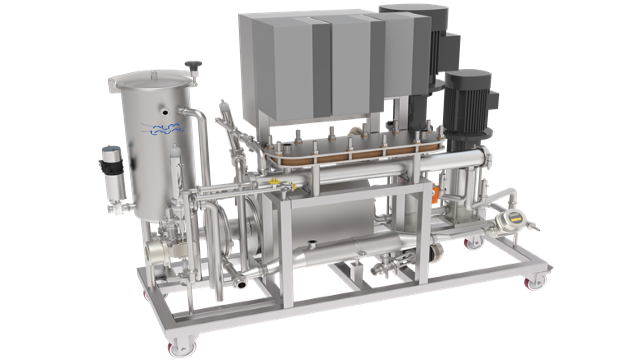

If your process requires more advanced separation than microfiltration MF can provide, Alfa Laval supplies a complete portfolio of membrane solutions, including nanofiltration NF, ultrafiltration UF and reverse osmosis RO, along with pilot testing units to validate process performance at each filtration level.

Want help choosing the right solution?

Submit the form to connect with our engineering experts and get personalized guidance for your filtration needs.