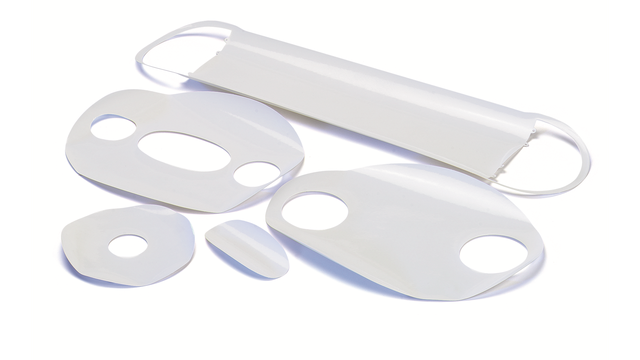

UF flat sheet

Membrane technology using ultrafiltration is widely applied across industrial applications due to its efficient and cost-effective separation performance. Alfa Laval’s portfolio of ultrafiltration membrane flat sheets covers a broad spectrum of flux properties and MWCO values, enabling precise control of retention and permeate quality. The application of our flat sheet UF membranes includes an array of demands in the dairy, pharmaceutical, biotech, food and beverages industries.

Ultrafiltration excellence with Alfa Laval membrane flat sheets

- Precise molecular separation with MWCO values ranging from ~1,000 to 100,000 Da, enabling targeted retention of proteins, fats and polysaccharides

- High separation efficiency at relatively low pressure reduces energy consumption and operating costs compared to alternative methods

- Compatible with plate-and-frame modules, available by the metre, as 20×20 cm standard sheets, or pre-cut to fit Alfa Laval systems

- UF pHt™ membrane series supports high pH and high temperature during CIP, enhancing membrane lifetime and reducing cleaning chemicals

- Proven in applications like protein concentration, enzyme purification and fermentation broth clarification, enabling recovery of valuable components

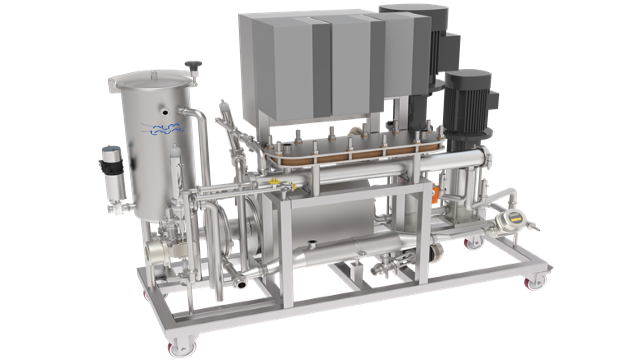

High-quality membrane ultrafiltration from lab to industrial scale

Ultrafiltration is a versatile separation process increasingly used in laboratory and industrial applications. The precise separation performance of Alfa Laval flat sheet UF membranes is outstanding across a broad range of processes, retaining ~90% of the solutes.

We offer unique capabilities in the purification, concentration and fractionation of a large array of macromolecules. Engineered to provide consistent molecular rejection along with high flux permeation, our flat sheet ultrafiltration membranes enable reliable separation performance. Modular configuration options allows easy scaling from lab testing to full industrial deployment.

Manufactured in Alfa Laval’s membrane center under rigorous sanitary controls with documented material traceability, our ultrafiltration equipment sets the market benchmark for compliance and quality assurance in hygiene-critical applications.

Alfa Laval offers a wide range of flat sheet membranes for ultrafiltration (UF) with different flux properties, molecular weight cut-off values and rejection capabilities. The membranes are made of different polymer types based on a unique construction of either polypropylene (PP) or polyester (PET) support material which provides optimum cleaning conditions.

FS, RC and ETNA types

This series of Alfa Laval flat sheet membranes for ultrafiltration covers the membrane types FS40PP, RC100PE, RC10PE, RC70PP, ETNA10PP and ETNA01PP.

- The FS membrane is made of fluoro polymer and has a MWCO value of 100,000.

- The RC membrane is made of regenerated cellulose acetate with MWCO values up to 100,000.

- The ETNA membrane types are made of composite fluoro polymer with MWCO values of either 1,000 or 10,000.

UF-pHt™ types

In this series of Alfa Laval flat sheet membranes for ultrafiltration you will find the GR40PP, GR60PP, GR61PP, GR70PP, GR80PP, GR90PP and GR95PP types. As the name of the type indicates, these membrane types are all characterized by their tolerance to high pH values and high temperatures.

- The GR40PP, GR60PP, GR61PP and GR70PP membranes are made of polysulphone with MWCO values ranging from 100,000 to 20,000.

- The GR80PP, GR90PP and GR95PP membranes are made of polyethersulphone with MWCO values ranging from 10,000 to 2,000.

Dairy UF-pHt™ types

The series of Alfa Laval flat sheet ultrafiltration membranes for the dairy industry covers the GR60PP, GR61PP, GR70PP, GR73PP and GR82PP membrane types.

- The GR60PP, GR61PP and GR70PP membranes are made of polysulphone with MWCO values of 20,000 and 10,000.

- The GR73PP and GR82PP membranes are made of polyethersulphone with MWCO values of 10,000 and 5,000.

How do flat sheet ultrafiltration membranes work?

Ultrafiltration (UF) is a pressure-driven membrane-based separation process widely used in industrial and research applications. A typical ultrafiltration membrane flat sheet features pore sizes in the range of approximately 2–100 nm, allowing effective separation at relatively low transmembrane pressures. This enables cost-efficient fractionation and concentration of macromolecules such as proteins, fats and polysaccharides, while allowing salts, sugars, organic acids and small peptides to permeate through the membrane.

Ultrafiltration equipment is also used for purification, clarification and recovery of valuable products in industries such as dairy, food and beverage, biotechnology and pharmaceuticals. Alfa Laval UF membrane modules are particularly effective for selective protein separation, especially in processes such as milk protein concentration and enzyme purification.

Explore related products

Should the performance of flat sheet UF membranes be compared with other Alfa Laval membrane flat sheets? Discover our complete portfolio and reach out for expert guidance during your testing and scale-up processes.