RO flat sheet

The RO membrane flat sheets from Alfa Laval are widely used across food, beverage, dairy, biotech and pharmaceutical processes. With pores so minute that only water and very low molecular weight compounds can pass through, this filtration method delivers reliable performance even under high temperatures and extreme pH conditions.

Experience durable RO membrane flat sheets for ultimate purity

- The most selective membrane in liquid separation, allowing only water to permeate

- Cover a broad spectrum of flux properties, pore sizes, molecular weight cut-off values and rejection capabilities

- Engineered to endure high temperatures and pH extremes during CIP operations

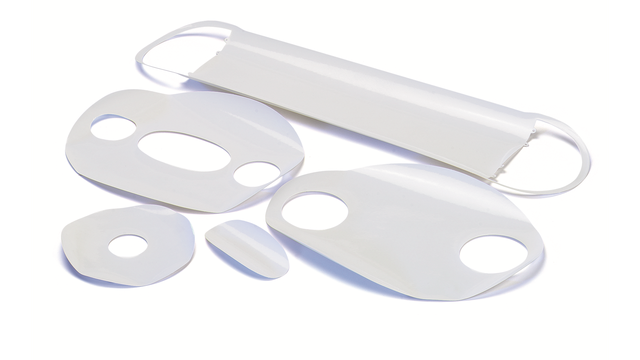

- RO flat membranes are available cut to fit plate-and-frame modules, in 20 × 20 cm pieces, or by the meter

- Supplied with all required lock and passage rings for sheet RO

Mapping the path to reliable RO performance

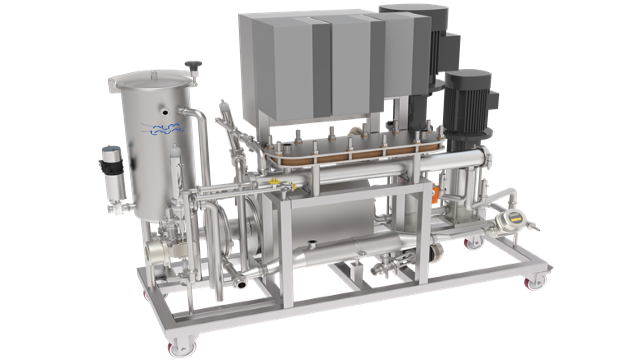

Finding the right reverse osmosis solution is a journey. The right membrane, with unique parameters like osmotic pressure, water flux and resistance, can mean the difference between the success and failure of the entire operation. Alfa Laval’s team of experts guides you through the process, from laboratory testing to full-scale operation.

LabUnits operate under controlled conditions, with typical transmembrane pressures (TMP) of 5–25 bar and fluxes ranging from 10–30 L/m²·h, depending on feed composition, temperature and membrane material. Standalone pilot systems can be equipped with either RO flat sheet membranes or RO spiral wound membranes to provide data under realistic operating conditions, including variations in feed, cleaning cycles and long-term fouling, so you can see exactly how your system will perform before it scales up.

Discover Alfa Laval RO flat membranes

Reverse osmosis membranes are typically defined by their structural design, base materials, geometric configuration and permeability characteristics. While various polymers can be employed, Alfa Laval’s polymeric flat sheet membranes for reverse osmosis are made of thinfilm composite layers supported on either polypropylene (PP) or polyester (PET). This robust design, available in both flat-sheet and spiral-wound configurations, ensures optimal cleanability and mechanical stability.

The RO membranes are available in the types: RO90 and RO99 membranes, which are cast on polyester support, with sodium chloride rejections of ≥ 90% and ≥ 98% respectively. The RO98 pHt™ membrane, which has a sodium chloride rejection of ≥ 98%, is cast on polypropylene support and is tolerant to high pH and temperature.

How does reverse osmosis work?

Reverse osmosis (RO) is a filtration method widely used in both industrial processes and the production of clean potable water. It purifies water by pushing it through a semi-permeable membrane that can remove ions, molecules and some larger particles, making RO one of the most selective filtration methods.

When an external pressure is applied to the solution side of the membrane, the solvent (usually water) passes freely through the tiny membrane pores, while solutes such as salts, sugars and impurities are retained on the pressurized side. Certain organic compounds with low molecular weights (solvent molecules) can also pass through, but only to a limited extent.

Alfa Laval reverse osmosis membranes are used for the high-flux concentration of either the direct feed stream or permeates from ultrafiltration and nanofiltration.

Explore related products

Perhaps you need more than RO membranes in your process. Alfa Laval’s comprehensive portfolio of membrane technologies includes MF membranes, UF membranes, NF membranes and testing capabilities to help you identify the optimal solution for your filtration needs.

Contact us to get started

Because RO relies on pressure-driven diffusion, its performance depends on factors like applied pressure, flow rate, temperature and feed composition. Alfa Laval’s team of experts is ready to help evaluate and optimize your process to achieve the desired purification efficiency.