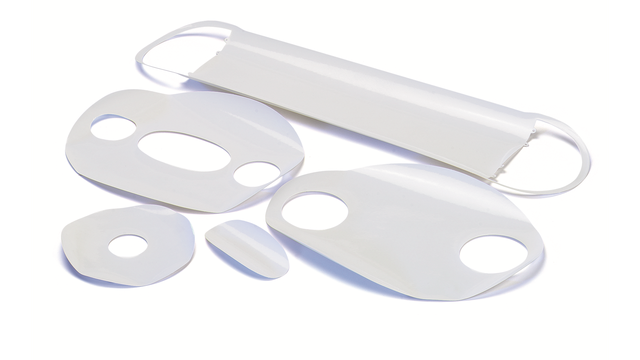

NF flat sheet

Alfa Laval’s nanofiltration flat membranes deliver exceptional performance for charge-sensitive feeds, where precise salt selectivity is essential for key applications in the food, beverage, dairy, biotech and pharmaceutical industries. NF flat sheet membranes are particularly effective for high-yield concentration and demineralization of products such as whey and ultrafiltration permeates, helping you maximize product quality and process profitability.

Alfa Laval nanofilter membranes make a difference

- High-yield concentration and selective demineralization

- Precise control of divalent and monovalent salts

- Effectiveness with charge-sensitive feeds

- Magnesium sulfate rejection ≥ 99%

- Robust, durable design for long service life

Flat sheet membranes for nanofiltration

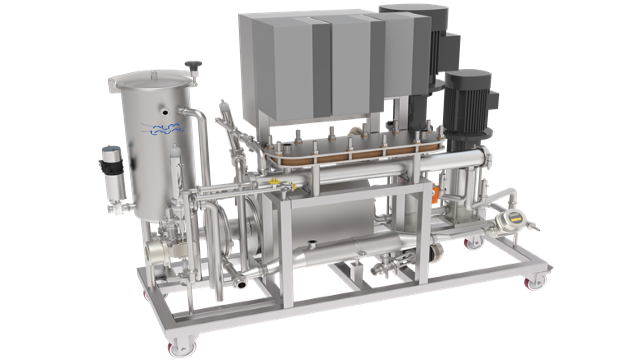

As one of the most effective methods for separating charge-sensitive feed streams in food and pharmaceutical applications, NF membranes are available in both flat sheet and spiral wound module configurations. If you are planning to build an NF treatment plant and need to determine which membrane is best suited to your process, you can start by testing multiple nanofilter membranes types at two scales: laboratory units for rapid screening and pilot plants for process optimization under realistic operating conditions.

Once you have identified the right membrane solution for your process, the Alfa Laval team of experts will provide support for scale-up, including module configuration, operating parameters and integration into full-scale industrial systems.

Why choose Alfa Laval NF membranes for high-precision separation?

NF membranes are available in both flat sheet formats for material screening and spiral wound module configurations for full-scale operation. Manufactured by the Alfa Laval Membrane Centre in Denmark from thinfilm composite material and supported by a unique construction of polyester (PET) material, the polymeric flat sheet membranes for nanofiltration create optimum cleaning conditions, allowing the NF membranes to perform reliably even in the most demanding processes.

The NF membranes are available in two types, NF and NF99HF, both offering magnesium sulfate rejection of ≥ 99%, a level of precision crucial for processes that require exact control over salt content.

How do NF membranes work?

Nanofiltration (NF) employs semi-permeable membranes with a typical molecular weight cut-off (MWCO) of ~150–1,000 Da. Alfa Laval flat sheet nanofiltration membranes operate at pore sizes as small as 300 Da and pressures of up to 55 bar.

Small ions and low-molecular-weight compounds pass freely through the nanofilter membrane, whereas larger ions and most organic components are retained, making NF membranes well-suited for high-yield concentration and demineralization of products such as whey and ultrafiltration permeate.

When your process demands filtering out large salts with a divalence greater than 2 and allowing essential monovalent salts to pass into the permeate, Alfa Laval NF membranes deliver unmatched performance. The selective filtration of NF membranes is a compelling option for applications like divalent salt removal, mineral control and specialty processes such as low-alcohol beverage production, where alcohol passes through but color, peptides, aroma and other delicate components remain in the retentate.

Explore related products

Should you need more than nanomembranes to remove unwanted bivalent ions, Alfa Laval offers a full range of membrane technologies for your process, including MF membranes, UF membranes and RO membranes, as well as pilot testing units to discover the right solution to optimize your filtration process.

Contact us to get started

Evaluate your nanofiltration process with Alfa Laval. Let our experts help you determine the optimal membranes, operating parameters and scale-up strategy for your application.