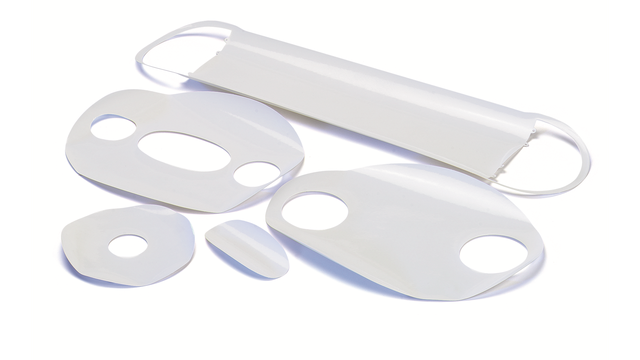

MF flat sheet

The selection of microfiltration flat sheet membranes from Alfa Laval covers different pore sizes and flux properties. These membranes are used in an extensive range of processes applied in the food, beverage, dairy, biotech and pharmaceutical industries, providing reliable separation performance tailored to specific process requirements.

Experience the benefits of Alfa Laval microfiltration flat sheet membranes

- Available with varying flux properties, pore sizes, molecular weight cut-off values and rejection capabilities to suit an extensive range of processes

- Offered by the metre, as standard sheets, or precut to fit Alfa Laval plate-and-frame modules

- Delivered with necessary lock and passage rings

- High tolerance to pH extremes and elevated temperatures

- Fully compliant with EU Regulation (EC) 1935/2004, EU Regulation 10/2011, EU Regulation (EC) 2023/2006, and FDA regulations (CFR Title 21)

Designed, developed and manufactured by Alfa Laval Membrane Centre

With pore sizes down to 0.1 μm, microfiltration membranes efficiently remove small-diameter dispersed solids, such as bacteria, fat and oil globules, without affecting the balance of dissolved components in the stream.

Widely employed across the food, beverage, dairy, biotech and pharma industries for a broad range of high-sanitary processes, including concentration and purification, clarification and fractionation, extraction, product recycling and recovery, and product and effluent upgrading.

The science behind microfiltration membrane material

Alfa Laval produces two series of microfiltration membrane flat sheets, each developed with unique properties to meet different process needs, such as flux, pore size, and rejection requirements, and designed to filter out tiny particles, bacteria, and other solids while preserving the valuable liquids they carry. Made from either polysulphone or fluoro polymers, the MF flat membranes are built on a special polypropylene (PP) support that enables easy cleaning and long-lasting performance.

MFG series

The MFG microfiltration membrane is made of polysulphone polymer. The membrane comes in two types: MFG1, with an ultra-fine 0.1 µm pore size, and MFG2, with 0.2 µm pores.

MFP series

The MFP series, made from durable fluoro polymer, offers MFP2 with 0.2 µm pores and MFP5 with 0.5 µm pores..

How does membrane microfiltration work?

Membrane microfiltration is a physical separation process that uses a thin, porous membrane to remove tiny suspended particles from a liquid. In microfiltration, particles such as bacteria, fat globules and fine sediments are simply too large to pass through the microscopic pores of the flat membranes (usually 0.1 to 1 micrometer in size) and therefore remain on the upstream side of the membrane – captured without altering the liquid’s natural chemistry.

Microfiltration membranes from Alfa Laval are highly cost-effective to operate, largely due to the gentle yet precise filtration mechanism, which requires minimal energy consumption. They also eliminate the need for frequent replacement and disposal of cartridges and other consumables used in traditional dead-end filtration.

Alfa Laval microfiltration membranes are exceptionally durable, with service lives that can exceed five years.

Explore related products

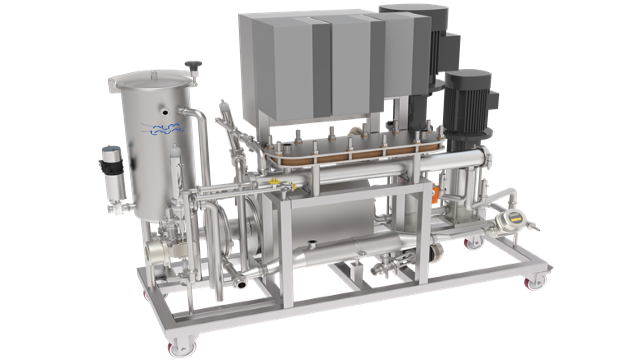

Microfiltration is sometimes used as a pre-filter because it has relatively larger pore sizes compared to other filtration methods. Should you need more than MF membranes, Alfa Laval offers a full range of membrane technologies for your process, including NF membranes for selective separation, UF membranes for fine particle removal and RO membranes for high-level purification, as well as pilot testing units to evaluate performance across all filtration stages.

Interested in seeing how MF membranes can add value to your process?

Reach out to Alfa Laval’s experts in microfiltration membrane materials and processes to help you find the right solution for your operation.