Flat sheet membranes

Alfa Laval manufactures polymeric membranes for a wide range ofapplications in the food, beverage, dairy, biotech and pharmaceutical industries. Our flat sheet membranes are ideal for pilot-scale laboratory testing and can also be used at industrial scale when stacked in membrane modules. They cover all cross-flow filtration processes: reverse osmosis, nanofiltration, ultrafiltration and microfiltration.

Experience the quality, safety and reliability of our polymeric membranes

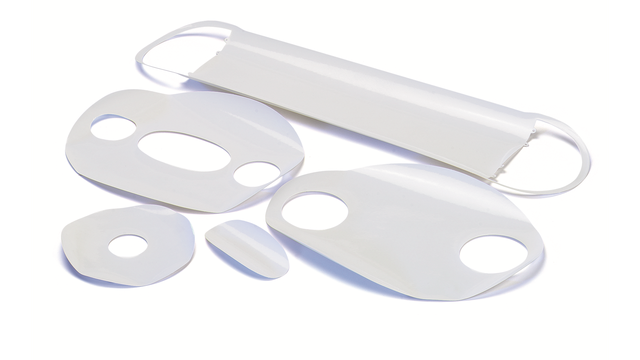

- Available by the metre, as 20 × 20 cm sheets, discs, or pre-cut sections, they fit all Alfa Laval plate-and-frame modules and are easy to replace

- High durability and cleanability thanks to polypropylene backing and pHt-resistant properties, tolerating up to 75°C and a pH range of 1–13

- Suitable for high-hygiene and high-value processes: concentration, purification, clarification, fractionation, extraction, recycling and upgrading

- Versatility across all filtration processes: reverse osmosis, nanofiltration, ultrafiltration and microfiltration

- Full regulatory compliance for safe use in food, dairy, biotech and pharmaceutical industries

Enhance efficiency and selectivity with Alfa Laval flat sheet membranes

Alfa Laval flat sheet membranes are primarily employed as testing membranes in laboratory and pilot-scale applications to evaluate performance in various membrane separation processes. They can also be installed in plate-and-frame membrane modules for industrial operation.

Available in both disc and sheet forms, Alfa Laval offers a wide range of testing membrane types designed to withstand high temperatures (up to 75°C) and a broad pH range (1–13). They are easy to replace when packed in modules.

All materials used in Alfa Laval membrane production comply with EU Regulation (EC) 1935/2004, EU Regulation 10/2011, EU Regulation (EC) 2023/2006 and FDA (CFR Title 21) requirements, ensuring suitability for food and pharmaceutical processing. These compliance standards also extend to equipment and fittings associated with membrane operations, including plate-and-frame units, element housings and pumps.

Which flat membrane should be used for each filtration process?

Choosing the right Alfa Laval flat sheet membrane depends on the level of separation you need. Microfiltration is best for removing suspended particles such as bacteria and fat globules. Ultrafiltration separates components by molecular weight, retaining proteins and larger molecules. Nanofiltration provides selective demineralization, allowing small ions to pass while retaining larger ones. Reverse osmosis delivers the tightest separation, permitting only water and trace salts to pass. Together, these options ensure precise control across all cross-flow filtration processes.

How does membrane filtration with flat sheet membranes work?

The basic technology behind membrane filtration with flat membranes involves using a semi-permeable, polymeric flat sheet membrane to separate a liquid into two distinct streams: permeate and retentate.

As the liquid is pumped across the surface of the membrane creates a positive trans-membrane pressure forces components smaller than the porosity of the membrane to pass through, forming the permeate. Any components larger than the pore size simply cannot pass through. They are retained and remain in the so-called retentate.

The flat sheet membrane is designed for cross-flow operation, meaning the liquid flows parallel to the membrane surface. This flow helps prevent blockages and keeps the membrane surface clean, ensuring efficient and continuous filtration.

Let’s find the right solution for your process

From purification and clarification to recycling and product upgrading, Alfa Laval’s polymeric membrane flat sheets handle all your cross-flow filtration needs. Contact us and let our experts guide you to the right solution.