Paper production

Alfa Laval has a wide range of equipment and many years of process know-how and development to help you increase the efficiency of several processes in your paper production by exchanging existing equipment with our more efficient solutions. In addition to modern separation technologies, our experience and equipment also cover stock preparation, steam and condensate systems, coating, lube oil and wastewater treatment plants.

Modern technologies that increase the efficiency of your paper making processes

- Proven short payback time – profit from extracting high-purity chemicals

- Improved heat recovery and energy efficiency

- Waste minimization

- Increased uptime and production

- Compact designs and small footprints

Alfa Laval has a broad range of tried and tested gasketed-and-welded heat exchangers for heating and cooling in various paper applications. We also have a range of centrifugal separators efficiently clean lube oil from water and particles to ensure a long working life and high uptimes, while our decanter centrifuges help minimize waste for disposal in wastewater treatment plants.

Increasing paper mill production efficiency with energy-saving solutions

Every paper mill is unique, but the challenges that mill operators face are many. Mill operators must find ways to remain profitable despite increasing labour, pulp and energy costs while maintaining mill productivity and product quality.

Getting the most out of raw materials using less energy and water while maintaining end-product characteristics requires process knowledge as well as the right technologies, equipment and services to extend performance. Alfa Laval understands what it takes to achieve all this throughout mill.

Improving energy efficiency in paper manufacturing processes

Energy accounts for up to 30 percent of the mill production costs. So it comes as no surprise that energy-intensive mills must focus on energy efficiency. Alfa Laval offers a broad range of solutions to optimize the use of energy at paper mills. These improve quality, productivity and reliability while delivering savings to the bottom line.

Boosting productivity with efficient drying and heat exchanger technology

Steam and condensate systems are critical in maximizing productivity and minimizing energy consumption. Compact, efficient and highly reliable, Alfa Laval heat exchangers are widely used throughout these systems. To meet your requirements for these high-temperature and/or high-pressure applications, Alfa Laval provides a wide range of heavy-duty heat exchangers, including gasketed, semi-welded and fully welded designs.

Advanced wastewater treatment solutions for sustainable paper mills

Processing large volumes of wastewater and residual sludge waste poses challenges for many mills. Alfa Laval offers a complete spectrum of wastewater equipment that helps minimize environmental impact and maximize energy savings. Water line applications include MBR, SBR, heat exchangers and tertiary filtration using membranes or cloth media. For sludge line applications, Alfa Laval offers a full range of equipment for thickening and dewatering.

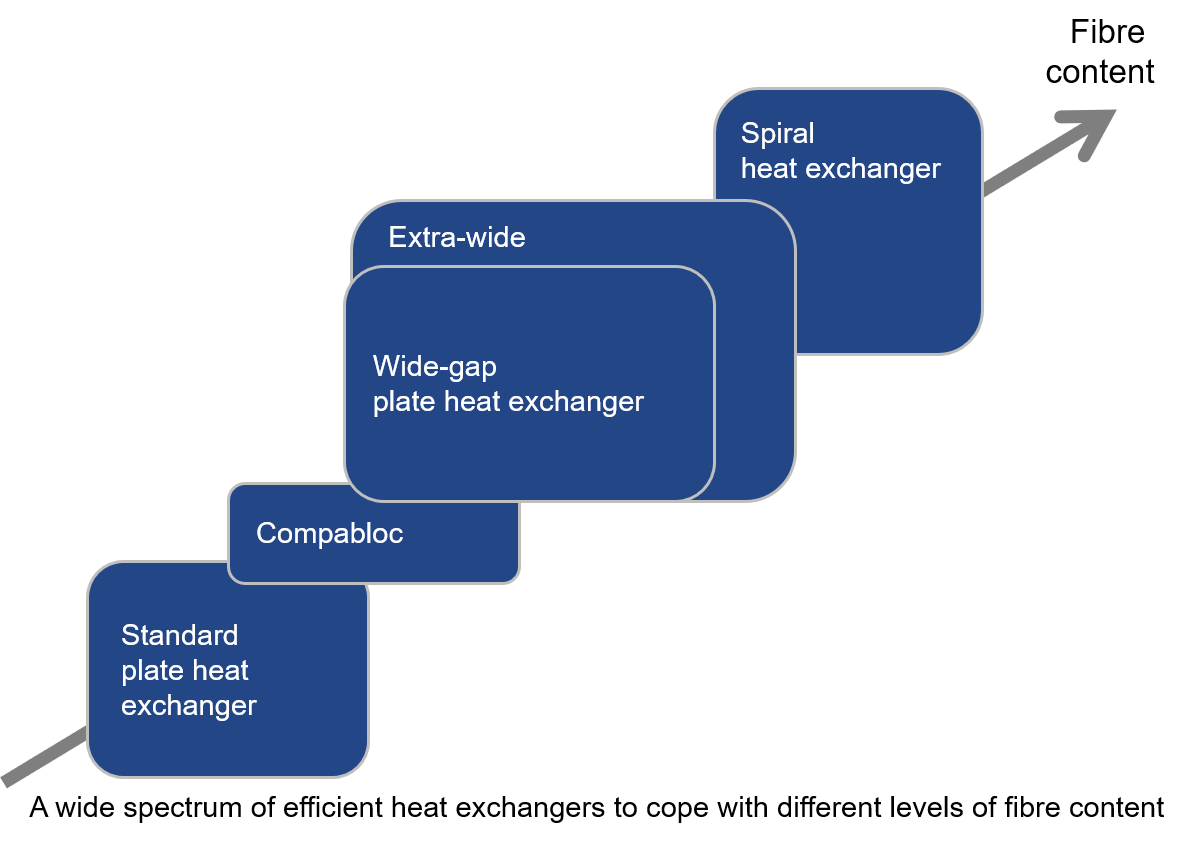

Easy handling of fibrous process fluids

Alfa Laval heat exchangers are optimized to process fluids containing fibers and other solids with ease while providing high thermal efficiency and maximum heat recovery. Other benefits include low installation, operation and maintenance costs as well as complete access to the heat transfer surface to ensure easy cleaning.

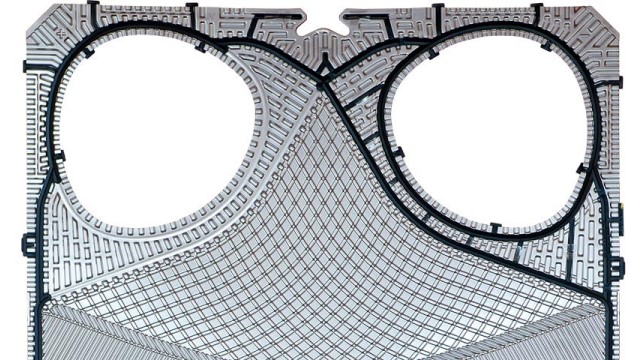

Gasketed plate-and-frame heat exchangers

Our Gasketed plate heat exchangers are optimizing heat transfer by large surfaces of corrugated plates drawing heat from one gas or liquid to the other. The high efficiency and an outstanding reliability in a compact design, offers an investment with the most attractive CTO over the product life time. Not to forget the energy saving capabilities and low environmental footprint.

Welded spiral heat exchangers

Alfa Laval spiral heat exchangers are designed to handle the toughest heat transfer challenges. Whether it’s frequent fouling from dirty media, or limitations from pressure drop and floor space, they are the ultimate problem solver for liquid-to-liquid and two-phase duties. The robust, efficient and compact designs keep both installation and maintenance costs extremely low, and they have a proven reputation for almost never fouling up

Compabloc

With over 30,000 units handling tough duties worldwide, Compabloc is the market champion when it comes to heat transfer. Laser-welded construction offers superior reliability in duties with aggressive media and high pressures and temperatures. Compabloc also offers 3-5 times the thermal efficiency of traditional shell-and-tube solutions, with a more compact design that is much easier to install and service.